Selecting the appropriate pipe for a borewell installation is crucial to ensuring a long-lasting and efficient water supply system. Whether you're setting up a borewell in regions like Assam or Jaipur, the right pipes play a critical role in the sustainability of the water extraction process. Factors like pipe size, material, and fittings need careful consideration to match the unique demands of the ground and water conditions in your area.

A well-chosen pipe system can prevent leaks, resist corrosion, and provide reliable performance over the years. This guide walks you through key aspects you need to know for making an informed decision regarding your Borewell Pipe needs.

Understanding Borewell Pipe Size Selection

The selection of pipe size is primarily guided by the diameter of the borehole and the pump specifications. Choosing a pipe size too small can result in reduced water flow and increased pressure loss. Conversely, excessively large pipes can lead to unnecessary expenses without corresponding benefits.

According to the Bureau of Indian Standards, the pipe diameter should closely match the borewell hole dimensions to maintain structural integrity and water yield efficiency. For example, in states like Odisha and Punjab, commonly used diameters range from 40mm to 160mm depending on borewell depth and yield.

Choosing the right pipe size means balancing flow capacity with durability. Typically, column pipes (the pipes extending inside the well) are selected based on the pump size, ensuring smooth water conveyance. The casing pipe, which stabilizes the borehole, is chosen to fit snugly within the drilled hole while allowing space for gravel packing, which filters out sand and debris.

Best Materials for Borewell Pipes

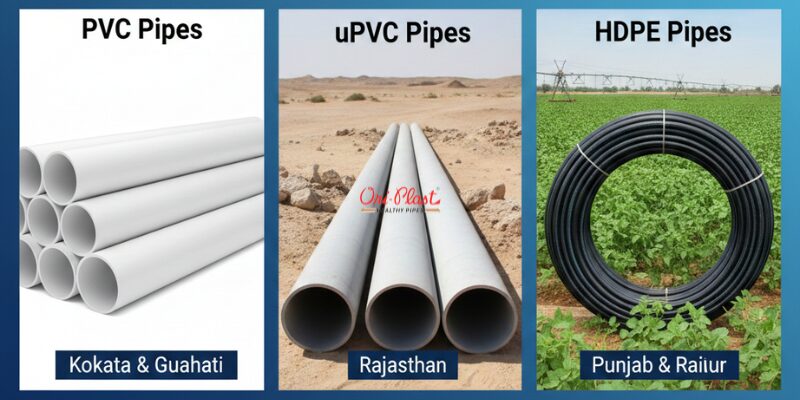

The materials used for borewell installation pipe systems have evolved significantly over the years. Traditional galvanized iron (GI) and mild steel pipes are gradually being replaced by PVC and uPVC pipes because of their resistance to corrosion and lighter weight.

- PVC Pipes: Commonly favored for their chemical resistance and durability. PVC pipes are lightweight, do not rust, and withstand harsh subsoil conditions. They conform well to IS standards and are widely used in Kolkata and Guwahati.

- uPVC Pipes: An upgrade over PVC, uPVC offers enhanced mechanical strength and better temperature resistance, making them ideal for varying climates and water qualities as found in Rajasthan.

- HDPE Pipes: High-Density Polyethylene pipes are flexible, resistant to cracking, and can handle high pressure. These pipes are gaining popularity for their long lifespan in agricultural irrigation projects, especially in Punjab and Raipur.

Image source : AI Generated

Image source : AI Generated

These materials also cater to various codified standards, such as IS 12818, ensuring reliability and safety in water supply.

Selecting the Right Borewell Pipe Fittings

Pipe fittings play an equally critical role as the pipes themselves. Leaks often occur not only due to pipes but because of poor-quality or incompatible fittings. Common fittings include couplers, elbows, tees, and adapters.

When selecting fittings:

- Ensure they match the pipe material and diameter to maintain a strong seal.

- Opt for fittings made from durable materials such as heavy-duty PVC or HDPE.

- Proper fittings protect the pipeline from wear and tear caused by ground movements or water pressure variations.

In states like Assam, where underground water table levels can be tricky, having the right fittings ensures a leak-proof and efficient borewell system.

Guidelines for Borewell Pipe Installation

Proper installation is as vital as selecting the right pipe. Verticality, adequate gravel packing around the casing pipe, and secure fitting joints are key to maintaining borewell performance.

- The casing pipe must be vertical to avoid wear on the borewell pump.

- Gravel packing with pea gravel around the casing pipe helps filter out sand while preventing contamination.

- Seal gaps and joints carefully to avoid ingress of surface water and soil.

- Disinfection of the borewell system via shock chlorination before commissioning is recommended.

In places like Jaipur and Raipur, adherence to these installation principles minimizes risks of clogging and improves long-term yield.

Image source : AI Generated

Image source : AI Generated The Bureau of Indian Standards provides detailed codes (such as IS 2800) that detail construction and testing procedures to ensure borewell efficiency and longevity.

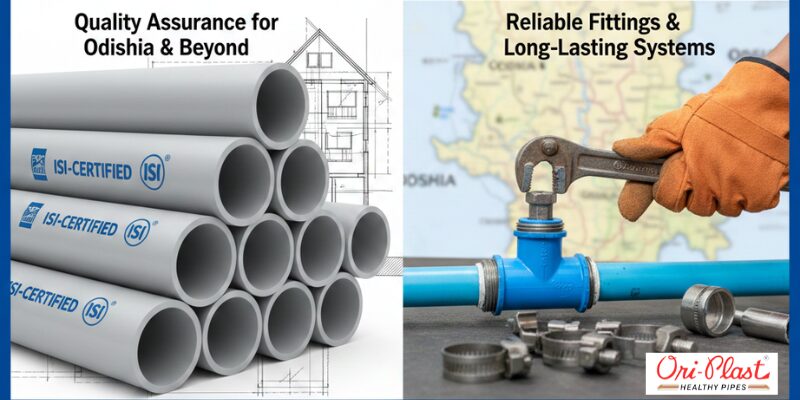

Why Choose ISI-Certified Pipes?

ISI certification acts as a quality assurance mark that suggests pipes have undergone rigorous testing. ISI-certified pipes conform to Indian Standards for dimensions, strength, and chemical resistance, minimizing chances of installation failure.

For buyers in Odisha and nearby regions, choosing ISI-certified pipes means investing in durable products that meet national benchmarks. This purchase decision reduces maintenance costs and boosts customer confidence in the product's performance.

Fitting the Pipes and Accessories

Accessories like clamps and adapters complement the pipe installation, ensuring tight, leak-proof connections. Quality accessories prevent joint failures and extend the system’s life.

Image source : AI Generated

Image source : AI Generated Conclusion

Investing time and effort in choosing the right pipe size and type for your borewell installation guarantees a dependable water supply that lasts for years. From selecting materials like PVC, uPVC, or HDPE to ensuring ISI-certified products paired with quality fittings and professional installation, each step contributes to the system's overall resilience.

Regions like Assam and Rajasthan benefit significantly from using pipes tailored to their unique groundwater and soil conditions. Remember, the upfront investment in quality pipes and fittings saves costs and headaches by preventing leaks, corrosion, and system failures later on.

Making the right choices today turns your borewell into a sustainable water source for tomorrow.

FAQs

How do I select the correct pipe diameter for a borewell?

Select based on borehole size and pump capacity to ensure efficient water flow without excessive pressure loss.What materials are best for borewell pipes?

PVC, uPVC, and HDPE are preferred due to durability and corrosion resistance.Why is ISI certification important for pipes?

ISI certification ensures the pipes meet quality, safety, and performance standards.Can I mix different pipe materials in my borewell?

It’s best to use compatible materials throughout to avoid joint failures.How often should borewell pipes be inspected?

Annual inspections are recommended to detect damage or blockages early.What fittings are necessary for borewell pipes?

Couplers, clamps, elbows, and adapters suitable to pipe size and material.How does gravel packing support borewell pipe installation?

It filters out sediment and stabilizes the pipe against soil pressure.Is PVC better than uPVC for borewells?

uPVC offers higher strength and temperature resistance, making it preferable in some cases.What factors affect pipe choice for agricultural borewells?

Water volume, soil type, and chemical exposure influence the material choice.How does pipe installation impact borewell lifespan?

Professional installation with proper alignment and sealing prevents damage and ensures longevity.Are HDPE pipes flexible enough for borewells?

Yes, HDPE pipes are flexible and resistant to cracking under pressure.Can borewell pipes corrode over time?

Metal pipes like GI can corrode; PVC and HDPE resist corrosion effectively.Do pipe sizes affect pump performance?

Incorrect pipe size can reduce water flow and stress the pump.What maintenance do borewell pipe systems require?

Periodic cleaning, inspection of joints, and leak repair.Is disinfection necessary after installation?

Yes, shock chlorination helps remove contaminants from the system.What is the difference between column and casing pipes?

Column pipes carry water to the surface, while casing pipes stabilize the borehole walls.Can borewell pipe fittings cause leaks?

Poor-quality or incompatible fittings are a common source of leaks.

Image source : AI Generated

Image source : AI Generated