In today’s evolving infrastructure landscape, trust in every pipe is not just a preference but a necessity. Whether it's a municipal water system, a large-scale irrigation project, or a rural water supply network, civil engineers, contractors, and procurement heads alike demand materials that are certified, safe, and built to last. Recognizing this need, Ori-Plast, a leading certified pipe manufacturer in India, has secured two major certifications: ISO 45001:2018 and WRAS-certified electrofusion fittings. These milestones reflect Ori-Plast’s unwavering commitment to quality, safety, and compliance in the world of industrial and rural water piping.

In this blog, we explore how these certifications strengthen Ori-Plast’s position in the piping industry and why they matter for engineers and project planners who prioritize long-term performance and occupational safety.

Why Certifications Matter in Piping & Infrastructure Projects

Certifications are not just badges of honor; they are proof of a company’s commitment to compliance, quality control, and performance. In infrastructure development — especially water supply and sanitation projects — even a small failure in a pipe joint fitting can lead to huge setbacks. With increasing focus on quality in initiatives like Jal Jeevan, Smart Cities, and rural water connectivity, having verified and certified HDPE pipes is a necessity.

Ori-Plast Electrofusion fittings, widely used for underground water supply and pressure piping systems, are only as reliable as the fittings that connect them. At the same time, manufacturing these components under strict safety and quality management is critical to ensure leak-proof systems.

ISO 45001:2018 – Prioritizing Health & Safety in Pipe Manufacturing

ISO 45001:2018 is an internationally acclaimed standard that sets the framework for effective Occupational Health and Safety Management Systems (OHSMS). It sets the benchmark for organizations committed to reducing workplace risks, ensuring safe working environments, and proactively managing health and safety hazards.

For a large-scale pipe manufacturer like Ori-Plast, this certification is especially important. The production of HDPE, uPVC, and Electrofusion fittings involves complex machinery, high temperatures, and precision handling. With ISO 45001 compliance, Ori-Plast demonstrates that:

- Worker health and safety protocols are standardized and consistently monitored

- Risk management is built into every manufacturing process

- Employee training and emergency preparedness are part of core operations

Why It Matters to You

For civil engineers and contractors working with Ori-Plast products, ISO 45001 certification means you are working with a vendor that values people, process, and precision. It reflects an ethical and sustainable supply chain, reducing the likelihood of production delays or quality defects due to safety lapses.

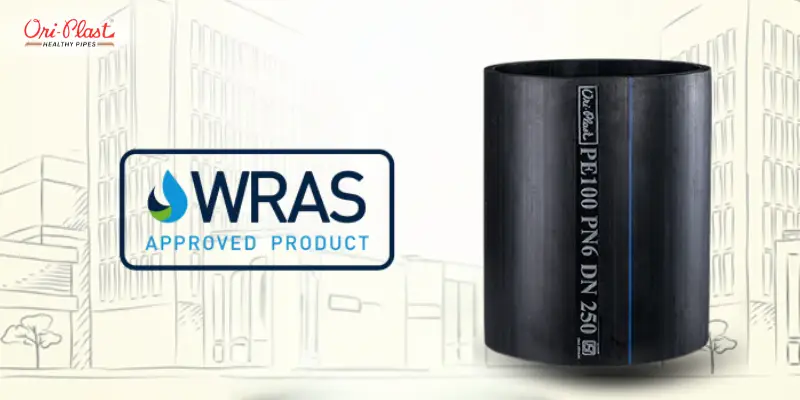

WRAS Certification – Assurance for Electrofusion Joint Reliability

The Water Regulations Advisory Scheme (WRAS) certification is a mark of compliance with global standards for water systems, especially in pressure and potable water applications. When it comes to Electrofusion fittings used with HDPE pipes, WRAS certification validates that the fittings are safe, leak-proof, and suitable for use in critical water infrastructure.

WRAS approval ensures that the materials used in Ori-Plast's electrofusion fittings are non-toxic and suitable for contact with potable (drinking) water, in compliance with the UK Water Supply (Water Fittings) Regulations.

The WRAS-certified fittings are made from black coloured, injection moulded PE 100, suitable for use with water up to 65°C. The WRAS Approval Number is 241255066.

Ori-Plast’s WRAS-certified electrofusion range includes elbows, couplers, end caps, tapping saddles, and reducers — all manufactured to support high-pressure systems and long-term underground usage.

Benefits of WRAS-Certified Electrofusion Fittings:

- Strong, homogenous joints that resist leaks

- Corrosion-resistant, even in aggressive soil conditions

- Perfectly suited for rainwater harvesting systems, rural drinking water networks, and municipal distribution lines.

- Easier installation with automated welding

Ori-Plast’s Quality-First Manufacturing Approach

Certifications alone are not enough — consistent delivery of quality products is the real benchmark. Ori-Plast backs its ISO 45001 and WRAS achievements with a robust internal quality control (QC) system:

- In-house testing labs for pressure, thermal stability, and dimensional accuracy

- Material traceability and batch-wise testing

- Use of virgin, non-toxic HDPE and uPVC raw materials

- Advanced extrusion and injection molding technology for precision manufacturing

From rainwater harvesting systems to rural pipeline projects, Ori-Plast pipes are designed to withstand environmental stress, flow pressure, and long-term use.

How These Certifications Benefit Stakeholders

Benefits for Civil Engineers

- Ease of specification and approvals with verified, standard-compliant products

- Long-lasting pipe joint fittings for HDPE water pipelines

- Compatibility with automated fusion welding machines

Benefits For Contractors

- Faster installation due to quality-controlled fittings

- Reduced post-installation failures and leakages

- Competitive edge in government or tender-based projects requiring certifications

Procurement Teams

- Simplified vendor qualification due to global certification compliance

- Reliable sourcing from a certified pipe manufacturer in India for long-term infrastructure investments

Benefits Project Owners

- Assured safety, sustainability, and water efficiency

- Reduced risk of service disruption due to pipe failures

- Alignment with national missions like Jal Jeevan and AMRUT

Trust in Every Pipe: More Than a Tagline

"Trust in Every Pipe" is not just Ori-Plast’s brand promise — it’s a philosophy built into every aspect of the company. From sourcing raw materials to final product dispatch, Ori-Plast ensures that each pipe, joint, and fitting delivers reliability under real-world conditions.

Whether you're working on:

- A borewell recharge project

- A rainwater harvesting plumbing system

- A rural drinking water line

- Or an urban pressure pipeline

Ori-Plast's certified HDPE pipes and pipe joint fittings deliver on performance, safety, and durability.

And if you're exploring additional industry-recognized certifications, read our previous blog on Bhutan Standards Bureau-certified HDPE pipe — which highlights Ori-Plast’s ongoing commitment to sustainable, globally compliant manufacturing.

Conclusion: Setting a New Benchmark in Indian Piping

With ISO 45001:2018 and WRAS certifications, Ori-Plast strengthens its position as a forward-thinking, reliable, and certified pipe manufacturer in India. These milestones are not just recognitions — they are promises kept, systems improved, and standards raised.

In an industry where pipe failures can lead to wasted resources and reputational damage, choosing a certified partner is critical. Ori-Plast’s certified range of HDPE pipes, uPVC pipes, and WRAS-certified electrofusion fittings ensures that your project stands the test of time — and monsoons.

Looking to build with confidence? Choose Ori-Plast – where every pipe is a promise you can trust.