When it comes to maintaining a hygienic and efficient home drainage system, SWR pipe installation plays a pivotal role. These pipes, specialized for soil, waste, and rainwater drainage, guard your home against leaks, clogs, and unpleasant odors. Installing a durable SWR pipe installation system ensures your plumbing flows smoothly and remains maintenance-free for years to come. This guide breaks down everything from essential planning to securing leak-proof joints, with tips tailored to plumbing needs in cities like Guwahati and Jaipur.

Understanding SWR Pipe Installation Basics

Soil, waste, and rainwater (SWR) pipes made from robust PVC that resists corrosion and chemical damage. A reliable plumbing network with SWR pipes ensures that wastewater is efficiently channelled out without backflow or foul smells invading your living space.

Planning your pipe route is the first critical step. This means choosing a path with a proper slope—typically a ratio of 1:40 is recommended—to ensure gravity helps wastewater flow away seamlessly. For instance, leaky or improperly sloped pipe systems in cities like Assam often cause drainage headaches and unpleasant odours.

Cutting and preparing pipes precisely is essential. Pipes should be cut squarely and deburred to avoid damaged edges that can compromise seals. Cleaning the pipe ends thoroughly before joining prevents installation issues and keeps the connection water-tight.

The Step-by-Step SWR Pipe Installation Process

Planning & Route Setup

Start by mapping your drainage system layout, including the locations for waste outlets and inspection chambers. Ensure the pipes will have a consistent downward slope for free-flowing drainage without blockages.

Cutting & Cleaning Pipes

Cut pipes using a PVC pipe cutter and smooth edges with sandpaper or a file. Dirt, grease, or moisture on the pipe's joining edges must be wiped with a clean dry cloth to secure perfect adhesion when using solvent cement.

Applying Solvent Cement or Rubber Ring Seals

SWR pipe installation employs two main jointing methods: solvent cement and rubber ring seals. Solvent cement chemically bonds pipes and fittings for a permanent, leak-proof connection, widely used in regions like Odisha for robust installations. Rubber ring joints offer flexible, cost-effective seals mostly for quick fixes or expansions.

Joining Pipes & Fittings

Join pipes by inserting cleaned and cemented ends into fittings, twisting slightly to ensure full engagement. Hold until the joint sets, usually for 30 seconds to a minute, ensuring no gaps form. This method guarantees the leak-proof strength essential for home drainage systems.

Testing for Leaks

After installation, testing the system by running water or air pressure helps detect leaks early. Fix any weak connections by reapplying cement or replacing faulty fittings before burying the pipes.

Common Installation Challenges & Troubleshooting

Homeowners in places like Punjab experience leakage and odour issues predominantly due to uneven slopes or poorly secured joints. These problems can cause water backflow or foul smells amidst plumbing networks, particularly in soil waste lines. Proper SWR pipe installation practices prevent this by emphasizing sealed joints and pipe alignment.

Another issue is the use of incompatible pipe fittings, which can cause stress points leading to breakage or leaks. Choosing ISI certified pipes and fittings from trusted manufacturers like Ori-Plast ensures compatibility and durability.

Maintenance Tips for Long-Lasting SWR Pipe Installation

Periodically inspect visible pipe sections and joints for signs of wear, corrosion, or leakage. Keeping inspection chambers accessible helps with regular cleaning and blockages removal, ensuring odour-free drainage.

For homes in Raipur or Kolkata where monsoon rains are heavy, ensuring that rainwater pipes are not clogged by debris protects your SWR pipe installation system from overflow damage.

Why Choose SWR Pipes for Your Home Drainage?

SWR pipe installation is indispensable for effective plumbing due to:

- High durability and chemical resistance.

- Leak-proof and odour-resisting joint systems.

- Lightweight and easy installation.

- Compliance with national ISI standards for plumbing.

This makes them ideal for multifaceted uses, including sewage and rainwater management in rapidly developing Indian cities with varied climatic conditions.

Importance of Quality Fittings in SWR Systems

One of the most vital components that complement SWR pipe installation are the fittings. Compatibility between pipes and fittings ensures there are no weak links that could trigger leaks or blockages.

Innovative Jointing Techniques

Recent advancements have streamlined SWR pipe installation. The introduction of solvent cement jointing and rubber ring sealing techniques offer durable solutions. The solvent cement forms a chemical bond that virtually fuses pipe and fitting together while rubber ring joints provide flexibility and cost-efficiency during repairs or expansions. This dual approach suits various scenarios—residential or commercial.

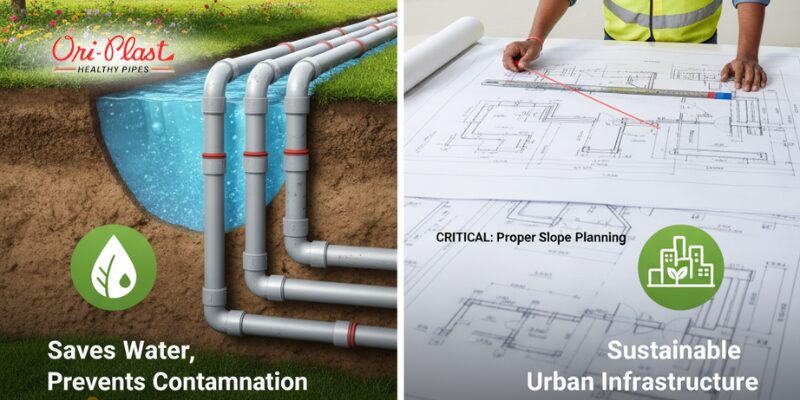

Environmental Benefits of Using SWR Pipes

Beyond efficient drainage, SWR pipe installation contributes positively to environmental management. Durable pipes reduce water wastage from leaks, while their chemical-resistant nature prevents soil contamination. Cities like Jaipur are adopting these systems as part of sustainable urban infrastructure planning to safeguard groundwater and enhance sanitation.

Professional Installation vs. DIY

While some handy homeowners attempt self-installation, professional SWR pipe installation guarantees alignment, slope accuracy, and leak-proof joints that comply with regulatory standards. Experts ensure inspection chambers are correctly placed and systems are pressure-tested prior to backfilling, reducing long-term maintenance headaches.

Planning for Future Maintenance

Incorporating inspection chambers in strategic spots simplifies routine cleaning and troubleshooting. This foresight is crucial in heavy rainfall zones such as Guwahati where drainage systems endure high stress. Accessible chambers enable timely removal of blockages without invasive digging.

Building Sustainable Drainage Networks

Proper planning, quality materials, and periodic inspections form the backbone of a sustainable drainage network. When each component—from pipes to inspection chambers—is installed with long-term functionality in mind, maintenance becomes easier, efficiency improves, and costly repairs are minimized.

FAQs on SWR Pipe Installation

What does SWR pipe installation mean?

It refers to installing Soil, Waste, Rainwater pipes used in home drainage.How do I ensure leak-proof joints during SWR pipe installation?

Use solvent cement properly and ensure clean, square cuts on pipes before joining.Can I install SWR pipes myself?

Basic installation can be DIY, but complex systems need professional help.What are common fitting types used in SWR pipe systems?

Solvent cement fittings and rubber ring joints.What sizes do SWR pipes come in?

Typically 90mm to 110mm diameters.How do I clean the ends of pipes before joining?

Remove dirt, grease and burrs using sandpaper and a clean cloth.What causes leaks in SWR pipe joints?

Incorrect cutting, poor sealing, or incompatible fittings.Is solvent cement harmful?

It’s chemical; use with care and ventilation.How to test for leaks in installed SWR piping?

Run water or air pressure tests before covering pipes.Which brand is best for SWR pipes?

Choose ISI certified pipes from known manufacturers like Ori-Plast.Is professional SWR pipe installation expensive?

Costs vary but ensure quality work saves repair costs later.Can SWR pipes be used in commercial buildings?

Yes, they are suitable for heavy-duty residential and commercial use.