HDPE pipes are the best POLYETHYLENE pipes for outstanding durability and the cleanest water supply. It is a versatile material suitable for various piping applications and one of the most common pipes used in residential and commercial construction projects. You can transport all sorts of fluids through HDPE pipes without worrying about your pipe getting corroded or damaged.

However, not all HDPE pipes are manufactured equal. There are various types of HDPE piping materials, and each one has its own set of specialities. Read on to find out which one is right for your requirements. We'll go through some essential things to consider when purchasing HDPE pipes or choosing the right HDPE pipe manufacturers.

What is HDPE?

HDPE or High-Density Polyethylene is a strong, durable, and flexible thermoplastic material. Strong molecular bond and impermeability make HDPE pipes leakage-free, a perfect alternative to steel and concrete main pipes carrying fluids and gases. Also, HDPE can be joined following various welding methods like,

- Butt fusion (the most reliable and easily joinable)

- Electrofusion

- Extrusion

- Socket welding

It makes HDPE versatile for various piping applications. You can transport all sorts of fluids through HDPE pipes without worrying about design limitations.

The Different Types of HDPE Pipes & Fittings

HDPE (high-density Polyethylene) pipes come in different grades, specifications depending on nominal pressure ratings and material quality. Nominal pressure rating indicates the maximum pressure that an HDPE pipe can survive. In terms of material quality, HDPE pipes are usually rated from PE 63 to 100. The higher the PE value, the greater are the Minimum Required Strength, Stress Crack Resistance and Rapid Crack Propagation Resistance.

- Minimum Required Strength-It is the characteristic of any material that provides long term strength and resistance to deforming under continuous stress.

- Slow Crack Resistance-Slow crack is a significant challenge and a common failure in an underground piping system built to survive for multiple decades. High PE rated HDPE pipes offer excellent resistance to slow crack for reliable longevity.

- Rapid Crack Propagation Resistance - It is another critical material property for an underground main piping system. As the name suggests, this material characteristic helps contain any crack and prevent it from spreading linearly.

Some of the standard HDPE piping and fittings products are,

- HDPE pipes

- HDPE tee

- HDPE fabricated equal tee,

- HDPE flange

- HDPE long neck pipe end

- HDPE end cap

- HDPE blind flanges

- Bend (Fabricated)

- MS Flange

- Reducer (Step1)

- Reducer (Step2)

- Reducer (Step3)

- Reducer (Step4)

- ZUT PUT Coupling

- PE Coupling / Expansion Joint

- Handi Band SS Repair Clamp

- Finger Repair Clamp

Client requirements: HDPE pipes suitable to your Project

HDPE pipes offer the best performance and value for money for residential and commercial consumers. Some of the salient consumer benefits of using HDPE in piping systems are,

- Trenchless installation-Perfect material for trenchless installation reducing the cost of installation.

- Zero-leakage performance-HDPE offers leakage-free performance, preventing contamination and water flow loss. It saves money.

- Jointless construction - allows lower lifecycle ownership cost of HDPE piping system due to easy installation of zero chances of leakage from pipe connectors.

- Environment friendly - HDPE is environment-friendly piping material as it does not allow contamination of water and ground soil. It is also energy efficient due to the ease of installation.

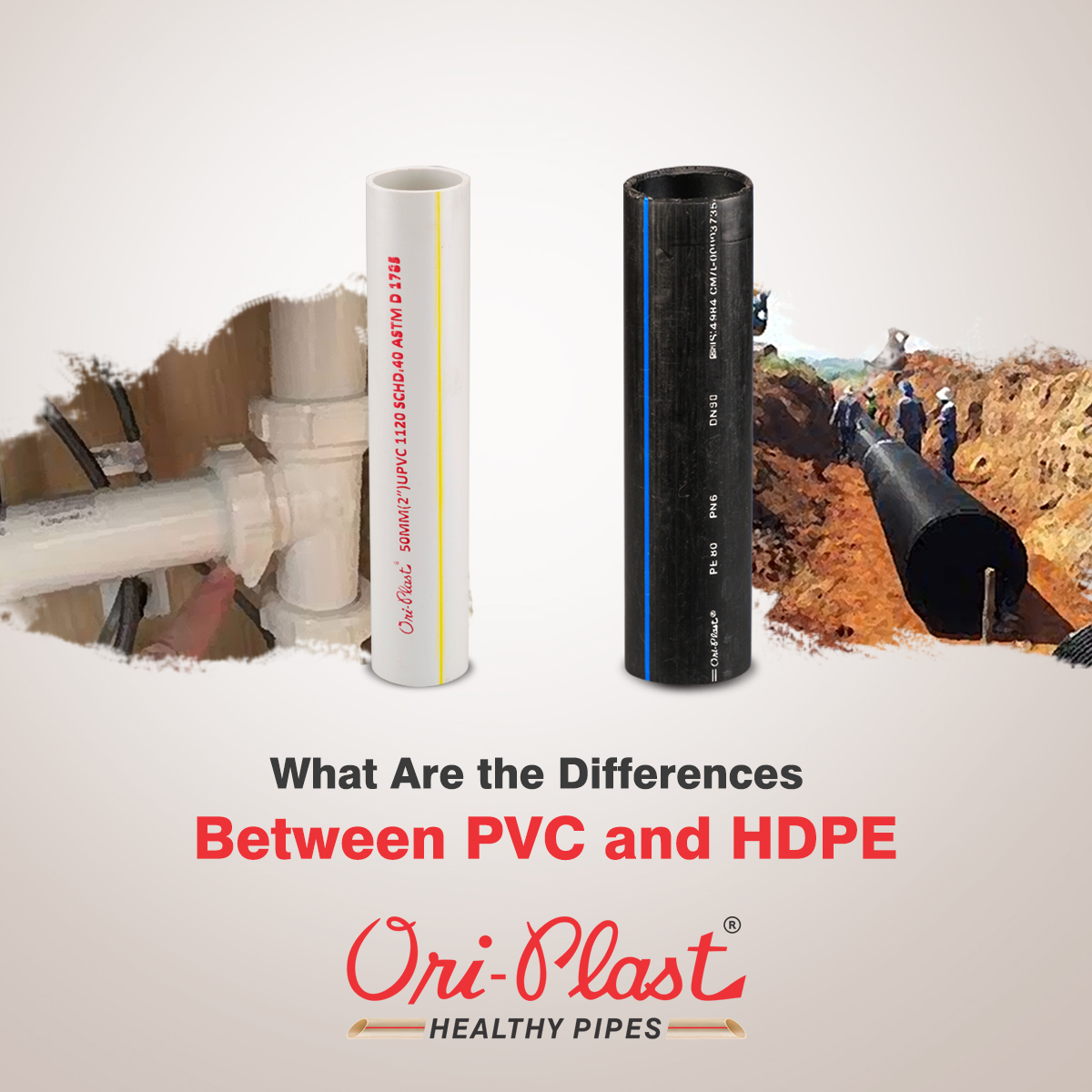

When purchasing HDPE piping for any project, you need to ensure that it's the correct type of HDPE for your requirements. The usages of HDPE is rapidly increasing, and the major HDPE piping applications are:

- Potable water supply line

- Water lines in hilly regions

- Irrigation lines

- Industrial effluent disposal lines

- Sewage and gas lines

- Fuel gas line

- Mining applications

Each of the above applications has specific requirements like different combinations of high crack resistance, flexibility to bending, resistance to crack propagation, high impact resistance, temperature resistance and flow capability. So, it is essential to check the grades and specifications of HDPE pipes.

Choosing the Right HDPE Pipe Manufacturers

HDPE pipe manufacturing involves heating and extruding HDPE material through a die depending on the desired diameter of pipes. The die size also determines the thickness of an HDPE pipe’s wall. When choosing the right HDPE pipe manufacturers for your project, you should consider the following factors:

- The range of grades and specifications available

- Market reputation of the brand

- Varieties of projects serviced by the company

- Availability of products near the project location

- Aftersales customer support

- Lifetime ownership cost

Among India’s top HDPE pipe manufacturers, Ori-Plast is a prominent name for HDPE pipes and related products complying with various Indian and international quality standards and certifications -

- IS 4984

- IS 14333

- IS 1239 Part 1

Ori-Plast HDPE pipes and fittings are manufactured using BUTT Fusion techniques for quick, easy and reliable joining. Our customer-oriented HDPE pipe distributors’ network has served numerous mission-critical projects and is trusted by residential, commercial and industrial customers across India. So, you can rely on the consistency of HDPE pipe supply from Ori-Plast distributors.

Finally

Choosing the right HDPE pipe for your project is crucial for long-term operational success and value for money. Irrespective of the scope and size of your projects, Ori-Plast always assures the best deal. So, give Ori-Plast a call. Get the latest price quotations and other necessary detail from our HDPE pipe experts.