Reliable pipe joints matter more than ever when building infrastructure that lasts. Electrofusion fittings for PE pipes deliver leak-proof connections, slashing environmental waste in water supply and irrigation systems. Trusted manufacturers craft electrofusion fittings for PE pipes to meet India's growing demand for eco-friendly solutions that save resources over decades.

Rajesh, a contractor from a bustling industrial hub like Guwahati, faced constant leaks in his irrigation setup last season. Frustrated with repairs eating into his budget, he switched to electrofusion fittings for PE pipes. Suddenly, his system ran smoothly, water loss dropped, and crops thrived without extra maintenance. Stories like his show why electrofusion fittings for PE pipes gain traction among builders and farmers alike.

Why Electrofusion Fittings Beat Traditional Joins

Old-school methods like butt fusion or mechanical clamps often fail under pressure, leading to leaks that waste precious water. Electrofusion fittings, on the other hand, melt pipe ends together using controlled electric heat. This creates a seamless, monolithic bond stronger than the pipe itself.

No extra glue or bolts mean fewer failure points. In real-world tests, these joints withstand bursts up to 1.5 times operating pressure. For someone like Rajesh, this reliability translated to zero downtime during peak monsoon flows.

India's PVC and PE pipe sector sees pipes holding over 60% market share in water infrastructure, with demand surging due to rural schemes like Jal Jeevan Mission. Lightweight PE pipes paired with electrofusion fittings cut transport emissions further, making projects greener from start to finish.

Electrofusion Fittings Work Magic with PE Pipes

Ever wonder how a simple coil of wire inside the fitting turns plastic into a rock-solid seal? Technicians slide the PE pipe into the electrofusion fitting, scan a barcode for exact parameters, and clamp it tight. An electrofusion machine then sends current through embedded resistors, heating the interface to 200-250°C in minutes.

The molten PE fuses molecularly—no gaps, no weak spots. Cool-down takes about an hour per joint, but results last 50+ years. This process shines in tight spaces, like urban retrofits where swinging a fusion machine proves impossible.

Step-by-Step: Joining PE Pipes Effortlessly

- Prep the pipe ends: Clean and scrape for perfect contact.

- Insert into electrofusion fitting: Align precisely.

- Connect processor: It auto-calculates melt time based on size.

- Clamp and heat: Watch the magic as it bonds.

- Cool under pressure: Ensures a void-free joint.

Farmers in regions like Punjab report 30% less water loss after upgrades, proving electrofusion fittings deliver on promises.

Unlocking Longevity: Benefits for HDPE Pipe Life

HDPE pipes already boast a stellar rep for flexibility and corrosion resistance. Add electrofusion fittings, and you extend that lifespan even further. Joints flex with ground shifts, resisting cracks from earthquakes or soil settling.

Traditional joints degrade over time from UV exposure or chemicals. Electrofusion fittings embed protection right into the bond, shrugging off acids in agricultural runoff. One study showed HDPE systems with these fittings outlast rivals by 20-30 years, cutting replacement costs dramatically.

In Odisha's coastal fields, where salty groundwater challenges setups, locals swear by this combo. It keeps irrigation flowing season after season, boosting yields without environmental strain.

HDPE Electrofusion Fittings in Action

Picture trenches dug fast because electrofusion fittings weigh half as much as metal alternatives. Installation crews finish jobs quicker, reducing site emissions from idling machines. Plus, the low-friction interior of PE pipes means pumps work less hard—another win for energy savings.

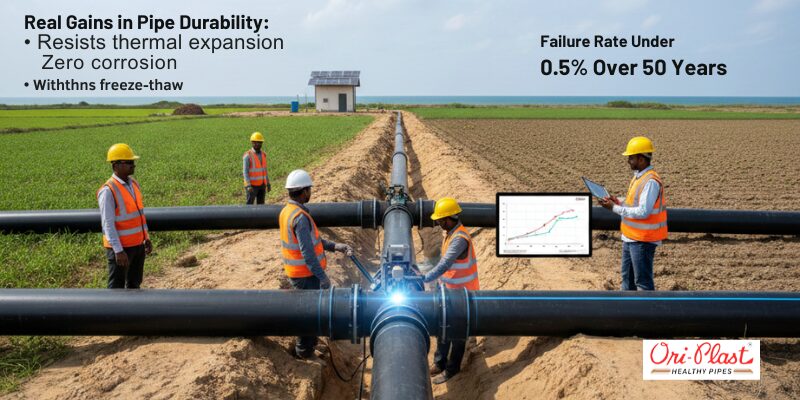

Real Gains in Pipe Durability

- Resists thermal expansion without buckling.

- Zero corrosion means no leaching into soil.

- Withstands freeze-thaw cycles in northern climes.

Stats reveal PE pipes with electrofusion boast a failure rate under 0.5% over 50 years, far below glued PVC joints.

Water Supply Wins with Electrofusion Fittings

Urban water grids leak up to 40% in older cities, squandering treated water. Electrofusion fittings seal PE pipes tight, ensuring every drop reaches taps. Their smooth bore minimizes turbulence, preserving pressure over long hauls.

In municipal projects, this means fewer breaks and repairs. Cities cut non-revenue water losses, vital as India's per capita availability dips below 1,500 cubic meters annually. Suppliers stock these for quick delivery, matching the rise in sustainable buys.

Raipur's planners adopted them for a recent expansion, noting smoother flows and happier residents. No more dry taps during peak summer demand.

Advantages in PE Water Mains

High-pressure tolerance suits mains up to PN16. Bacteria can't hide in seamless joints, upholding hygiene standards. Over decades, lower maintenance frees budgets for expansions.

Leak-Proof Joints Explained

The fusion melts surfaces into one layer, eliminating crevices where leaks start. Pressure tests confirm integrity before backfill, avoiding costly digs later.

Leak-Proof PE Joints: Electrofusion Fittings Explained

Leaks spell disaster—water waste, soil erosion, contaminated aquifers. Electrofusion fittings prevent this by creating homogeneous joints indistinguishable from the pipe wall. No O-rings to wear out, no flanges to bolt wrong.

In sewer lines, where methane buildup risks explosions, these fittings contain gases reliably. Their chemical resistance handles effluents without degrading, unlike rubber seals that perish.

A Jaipur contractor shared how his team fixed a failing network overnight using electrofusion fittings. Neighbors cheered as service was restored without digging half the street.

Science Behind the Seal

Heat melts polymers uniformly, diffusion bonds molecules across the interface. Post-cool, tensile strength exceeds parent material. Non-destructive tests like ultrasound verify perfection.

Why Leaks Vanish

- Molecular fusion > mechanical clamps.

- No human error in gluing.

- Vibration-proof for traffic-heavy zones.

Extending PE Pipe Lifespan Through Fusion

PE pipes endure, but joints often limit life. Electrofusion fittings match HDPE's 100-year potential, resisting fatigue from surges. In cyclic loading, they flex without fatigue cracks.

This longevity slashes embodied carbon—fewer remakes mean less mining, less energy. Recyclable at end-of-life, they loop back into new products seamlessly.

Assam's hilly terrains test pipes harshly, yet electrofusion setups hold firm against landslides and quakes.

Long-Term Electrofusion Strategies

Regular audits spot issues early. Pair with tracer wires for future locations. End-users save big on warranties up to 50 years.

Lifespan Boosters

- Optimal cure times prevent voids.

- UV stabilizers for above-ground storage.

- Compatible with PE100 materials.

Agricultural PE Piping: Electrofusion Benefits

Farmers lose billions to leaky drips. Electrofusion fittings enable precision irrigation, delivering water root-level without waste. Drip lines stay clog-free, nutrients mix evenly.

In Punjab's wheat belts, adoption spiked yields 15-20% via efficient delivery. Electrofusion handles high pressures for pivots, resists rodent chews better than PVC.

Kolkata outskirts see rooftop farms thriving on these systems, conserving rainwater smartly.

Tailored for Fields

Flexible layouts suit irregular plots. Low head loss maximizes distant emitters. Seasonal drains prevent winter bursts.

Eco-Perks in Farming

Saves 50% water vs open channels. Cuts fertilizer runoff into rivers. Boosts ROI in two seasons.

Maintenance Tips for PE Electrofusion Fittings

Keep joints pristine with simple habits. Inspect visually post-install—no melts, no burns. Avoid over-torque on clamps to prevent pipe ovality.

Store fittings shaded, ends capped. Use only certified processors for protocols. In service, monitor pressures quarterly.

Odisha growers train locals via demos, ensuring longevity.

Pro Tips for Longevity

Clean tools between uses. Log every joint's data. Train crews annually.

Common Pitfalls to Dodge

- Dirty surfaces weaken bonds.

- Wrong voltage risks under-melt.

- Rushing cool-down invites defects.

Market Stats: PE Demand Soars

India's PE pipe market grows at 8% CAGR, driven by irrigation mandates. Electrofusion fittings capture 25% of high-end installs, favored for zero-leak guarantees.

This piece wraps key insights on electrofusion fittings, sparking curiosity for more on sustainable piping. Readers like Rajesh find actionable tips here, leaving informed and ready to upgrade. Dive into next blogs for deeper dives on SWR or borewell innovations.

FAQs

What makes electrofusion fittings leak-proof?

They fuse PE pipe and fitting at a molecular level via electric heat, creating a seamless bond stronger than the pipe.How do electrofusion fittings work with PE pipes?

Pipe inserts into the fitting; a machine heats coils to melt and join surfaces, cooling into one solid piece.What are benefits of electrofusion for HDPE longevity?

Joints match HDPE's 50-100 year life, resisting cracks, corrosion, and pressure surges.Why choose electrofusion fittings for water supply?

They minimize leaks, preserve pressure, and ensure hygienic, high-flow delivery over distances.How do electrofusion joints extend PE pipe lifespan?

Homogeneous bonds prevent weak points, flexing with soil shifts for decades without failure.What advantages in agricultural PE piping?

Precision drips save water, resist clogs, and handle field pressures for higher yields.Maintenance tips for PE electrofusion fittings?

Inspect visually, clean before joining, use certified gear, and log parameters.Are electrofusion fittings eco-friendly?

Yes, they reduce leaks, extend life, and use recyclable PE, lowering overall carbon.Difference from butt fusion?

Electrofusion suits small spaces, needs no alignment jig, and automates parameters.Can electrofusion fittings handle high pressure?

Absolutely, rated up to PN16 for mains and drips.Best for irrigation in India?

Ideal for drip, sprinkler, and pivot systems, cutting water loss by 30-50%.How long to install a electrofusion joint?

10-15 mins prep and heat, 1 hour cool per size.Compatible with all PE types?

Yes, SDR9-41, PE80/100 grades.Cost vs traditional joints?

Higher upfront, but 40% savings over lifecycle from no leaks.Resistant to chemicals?

Fully, shrugs off fertilizers, salts, and effluents.Training needed for electrofusion?

1-day course covers scanning, processing, testing.Warranty on electrofusion fittings?

Often 10-50 years from makers like Oriplast.Use in sewer lines?

Perfect for gas-tight, corrosion-free joints.Impact on water quality?

Inert PE prevents taste, odor, or contamination.Storage tips for fittings?

Cool, dry, capped ends, away from UV.Testing electrofusion joints?

Hydrostatic pressure or ultrasound post-cool.Why PE over PVC for electrofusion?

PE's flexibility and fusion ease suit dynamic soils better.