The industrial world is witnessing a transformation driven by modern piping solutions that combine strength, flexibility, and smart technology. Among these, PE pipe technology has emerged as a game-changer, offering unparalleled durability and versatility across industries. This blog delves into the fascinating innovations shaping PE pipes for industrial use, spotlighting breakthroughs that enhance performance, sustainability, and monitoring capabilities. Whether you are managing manufacturing pipelines or large-scale irrigation projects, these evolutions promise more efficient and reliable piping systems.

Why PE Pipe Technology Matters in Industry

Since their inception, PE pipes have stood out due to their resistance against corrosion, chemical wear, and environmental stress. These qualities make them ideal for demanding industrial settings, from chemical processing plants to mining and wastewater management. In states like Assam, where industrial infrastructure continues to expand, such durable materials underpin the region’s growing industries.

Advancements in PE pipe technology have increased the lifespan and safety of piping systems, reducing maintenance costs while ensuring seamless operations. This technology adoption aligns with global sustainability goals, as PE pipes are recyclable and require less energy for production compared to traditional materials. According to recent industry data, the global PE pipe market is projected to grow robustly through 2030, underlining the widespread trust in these innovations.

Image Source : AI Generated

Image Source : AI Generated Key Innovations Driving PE Pipe Technology

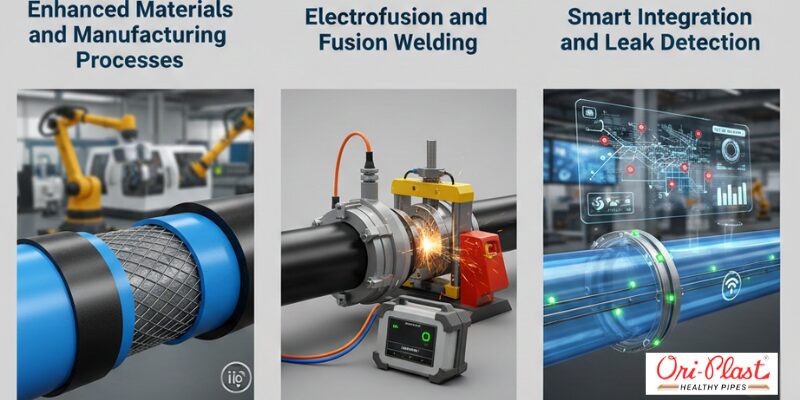

Enhanced Materials and Manufacturing Processes

The backbone of PE pipe technology lies in its evolving polymer compounds. Next-generation copolymer blends and nanocomposite materials now offer enhanced flexibility and superior crack resistance. These advancements ensure pipes withstand higher pressures and harsh chemical environments common in industrial setups.

Multilayer extrusion techniques allow for producing pipes that combine strength with lightweight design, significantly easing transportation and installation. Specialized reinforcements, including steel wire and fabric layers, further bolster mechanical properties—allowing use in high-stress applications.

Electrofusion and Fusion Welding

Joining pipes securely is crucial in industrial settings. Innovations in electrofusion technology now include improved fusion control systems, allowing for precise and reliable joints that minimize leakage risks. These systems often feature data logging and remote monitoring capabilities, ensuring quality assurance even in remote pipeline networks.

Fusion welding techniques like but fusion have also seen enhancements, offering faster installation with robust seals. These technologies are particularly valued in complex industrial pipelines where downtime is costly.

Smart Integration and Leak Detection

An exciting frontier in PE pipe technology is the integration of IoT-enabled sensors directly into piping systems. These sensors monitor flow rates, detect leaks, and flag anomalies in real time. Utilities and industrial facilities benefit from predictive maintenance, avoiding costly damage and resource losses.

Smart water management systems employing these smart pipes are becoming essential in expanding industrial hubs like Raipur, improving operational efficiency and reducing environmental footprint.

Image Source : AI Generated

Image Source : AI Generated Sustainability and Recycling

Efforts to improve sustainability include innovations in PE pipe recycling and use of bio-based raw materials. Enhanced recycling techniques reduce plastic waste, supporting circular economy principles. As industries in regions such as Odisha strive to meet environmental regulations, such advances in pipe technology align with broader green initiatives.

Industry-Specific Applications: Custom Solutions

PE pipe technology’s adaptability makes it suitable for diverse industrial applications—customized to meet unique requirements. For example:

- Mining operations leverage reinforced PE pipes with abrasion-resistant coatings.

- Chemical processing plants rely on high-grade PE formulations for corrosion resistance.

- Agricultural irrigation in states like Punjab benefits from flexible, UV-resistant PE piping networks.

Custom pipe manufacturing now includes tailored dimensions, wall thickness, and specialized fittings, all designed to optimize performance in specific environments.

Future Perspectives on PE Pipe Technology

Looking ahead, the future of PE pipe technology is bright with emerging trends such as:

- 3D printing for bespoke pipe fittings, speeding prototyping and reducing inventory.

- Advanced composite materials that further boost durability and environmental resistance.

- AI-driven monitoring systems enhancing real-time pipeline management.

Adoption of these innovations globally is expected to grow, fueled by industrial sectors demanding more reliable, efficient, and sustainable piping infrastructure.

Image Source : AI Generated

Image Source : AI Generated Conclusion

The latest innovations in PE pipe technology for industrial applications are revolutionizing how industries manage fluid transport and infrastructure durability. Advances in material science, such as enhanced polymer blends and multilayer extrusion, have allowed pipes to become stronger, more flexible, and resistant to chemical corrosion and environmental stress. Improved fusion welding and electrofusion fittings ensure leak-proof joints, critical for maintaining industrial pipeline integrity. Furthermore, the integration of smart sensors and IoT technology into PE piping systems enables real-time monitoring, predictive maintenance, and efficient resource management, especially important in expanding industrial regions like Raipur or Assam.

Sustainability remains a key driver in these innovations, with recyclable materials and eco-friendly manufacturing processes aligning with global and local environmental goals. Custom manufacturing capabilities allow industries across sectors—from mining in Odisha to precision agriculture in Punjab—to select and install pipes tailored to their specific needs, maximizing performance and cost-efficiency. Market trends project robust growth for industrial PE pipes worldwide, driven by the combination of durability, advanced technology, and sustainability.

FAQs

What are the latest innovations in PE pipe technology?

Advances include new polymer blends, multilayer extrusion, electrofusion with remote monitoring, and IoT-integrated smart pipes.How do electrofusion fittings improve PE pipes?

They ensure precise, leak-proof joints through controlled heating and fusion, improving pipeline reliability.How do PE pipes resist chemical corrosion?

They utilize high-density polymers and additives that create chemical-resistant barriers.What is the future of PE pipe manufacturing?

Future trends include 3D printing, AI monitoring, and sustainable materials use.What standards certify industrial PE pipes?

Standards like ISO 4427 and ASTM D3350 ensure quality and reliability.What is smart water management with PE pipes?

It involves using sensor-equipped pipes for real-time monitoring and efficient resource use.Can PE pipes be used in mining?

Yes, reinforced and abrasion-resistant PE pipes are tailored for mining applications.Are PE pipes sustainable?

Yes, advances in recycling and bio-based materials promote sustainability.How do multilayer PE pipes differ from standard pipes?

Multilayers combine different materials for enhanced strength and flexibility.What industries benefit most from PE pipes?

Water supply, chemical processing, mining, agriculture, and industrial manufacturing.How is leakage detected in smart PE pipes?

IoT sensors detect pressure changes and anomalies signaling leaks.Are custom PE pipes expensive?

Costs vary but tailored solutions optimize operational efficiency and durability.How flexible are PE pipes for industrial uses?

Highly flexible, reducing risks of cracks and suited for complex layouts.What is the typical lifespan of advanced PE pipes?

With new materials, lifespan exceeds 50 years under ideal conditions.Do PE pipes require special installation tools?

Special fusion welding and electrofusion tools are used for secure installation.Can PE pipes transport chemicals safely?

Yes, they are designed to resist a range of chemicals safely.What role does Assam play in industrial PE pipe usage?

Growing infrastructure projects in Assam increasingly use advanced PE pipes.