As the demand for sustainable energy solutions grows, solar water heating systems are becoming a preferred choice for many Indian homeowners, builders, and businesses. These systems offer significant savings on electricity bills, reduce dependence on fossil fuels, and help lower carbon footprints.

While most people focus on solar collectors or storage tanks when designing a system, one critical factor is often overlooked—the quality of pipes and fittings. These components ensure that hot water is efficiently transferred and safely contained, making or breaking the overall performance of the system.

In this blog, we’ll explore the key factors in choosing the right pipes and fittings for solar water heating systems and how Oriplast, a leading provider of high-quality piping solutions in India, can help.

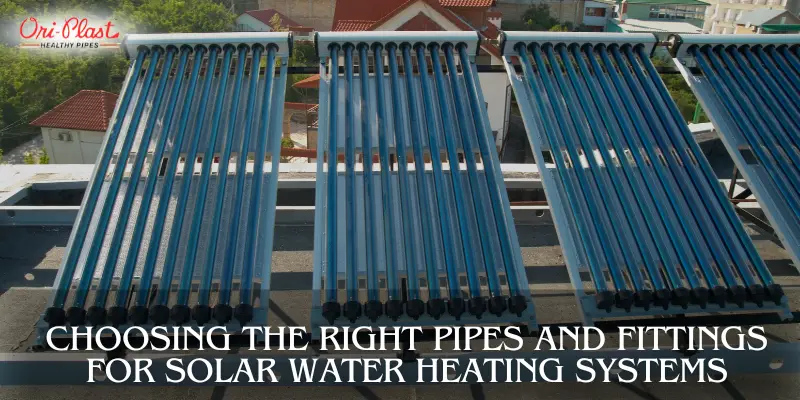

Understanding Solar Water Heating Systems

Solar water heaters use energy from the sun to heat water. Typically, cold water is pumped into solar collectors mounted on rooftops. These collectors heat the water, which is then stored in insulated tanks for domestic or commercial use. The system may operate on a direct (open-loop) or indirect (closed-loop) basis.

Regardless of the system type, piping is vital in transporting water between collectors, tanks, and end-use points. If subpar materials are used, the system may suffer from leaks, heat loss, corrosion, or early failure.

Why Pipes and Fittings Matter So Much

- High Temperatures: Solar water systems often heat water above 80–90°C, especially in peak summer. The piping must be able to handle this heat consistently without deforming.

- Pressure Fluctuations: Changes in water temperature cause expansion and contraction, generating pressure variations.

- UV Exposure: Pipes installed outdoors face direct sunlight and weathering.

- Water Chemistry: The system may circulate chemically treated water or antifreeze solutions.

- Durability: A failed fitting or cracked pipe can lead to expensive repairs or a complete system shutdown.

That’s why it's critical to select heat-resistant, pressure-rated, corrosion-proof, and UV-resistant piping systems—qualities that are core to Oriplast products.

Key Considerations When Selecting Pipes and Fittings

1. Temperature Resistance

Solar heating systems demand materials that can withstand high temperatures continuously. Among the best options:

- CPVC (Chlorinated Polyvinyl Chloride):

- Handles temperatures up to 93°C.

- Maintains shape and integrity under thermal stress.

- Ideal for hot water lines and rooftop installations.

- Other Options:

- PPR (Polypropylene Random Copolymer): Suitable up to ~70°C, making it less ideal for high-heat solar applications.

- Copper/Stainless Steel: Excellent thermal resistance, but costlier and prone to corrosion over time in certain water conditions.

Oriplast CPVC pipes are specially designed for hot water use and tested for long-term thermal performance.

2. Pressure Rating

Solar water heating systems operate under elevated pressure, especially those with pumps or in multistorey buildings. Pipes and fittings must be:

- Rated for continuous internal pressure.

- Compliant with Indian Standards like IS 15778 (for CPVC).

- Able to accommodate sudden surges or pressure drops.

Oriplast CPVC pipes are pressure-rated and meet the required ISI certifications.

3. Chemical Resistance

In closed-loop systems, glycol-based antifreeze or other chemical additives are often used. Pipes must resist:

- Chemical attack

- Scaling

- Internal deposits

CPVC pipes from Oriplast are chemically inert and resist scaling, even with hard water or treated fluids.

4. UV Resistance

Pipes running between collectors and tanks on rooftops are exposed to sunlight and heat. Prolonged UV exposure can weaken some plastics.

- UV-Resistant CPVC or UV-stabilized PERT options are ideal.

- Protective insulation or coverings are recommended for added safety.

Check with Oriplast’s technical team for UV-resistant pipe options or compatible insulation wraps.

5. Corrosion Resistance

Metal pipes may corrode over time due to:

- Mineral-rich water

- Electrolytic reactions

- Acidic pH levels

Plastic-based pipes like CPVC or PERT offer complete corrosion resistance, extending system life with little to no maintenance.

6. Ease of Installation

Solar heating systems often require careful installation in tight rooftop spaces. A good piping solution should offer:

- Easy handling and cutting

- Reliable joints with minimal tools

- Quick installation

Oriplast solar CPVC pipes join using solvent cement—fast, secure, and leak-proof. Their lightweight nature also makes rooftop work more manageable.

7. Cost-Effectiveness

While initial material costs are a consideration, long-term factors such as maintenance, lifespan, and energy efficiency matter more.

- CPVC offers the best value by balancing performance and cost.

- Oriplast’s quality manufacturing ensures fewer replacements and minimal downtime.

8. Adaptability to Indian Climates

India’s geographic diversity—from hot summers to monsoons—calls for resilient piping systems. Oriplast’s products are:

- Tested for high heat, humidity, and fluctuating weather.

- Backed by performance in thousands of installations across India.

Common Pipe Materials Used in Solar Heating Systems

✅ CPVC (Primary Recommendation)

- High-temperature and pressure-resistant.

- Corrosion-proof and chemical-resistant.

- Ideal for both domestic and commercial solar installations.

Oriplast’s CPVC range offers:

- Sizes from ½" to 2"

- Compatibility with standard fittings

- Long service life and low maintenance

Other Options (With Caveats):

- PPR: Good for warm water, but not ideal for solar peaks.

- Copper/Stainless Steel: Technically excellent, but cost and corrosion risks make them less practical for residential use.

- PERT: An emerging choice for flexible installations, available from Oriplast.

Don’t Overlook the Fittings

A system is only as strong as its joints. Solar systems require:

- Compatible materials: Use CPVC fittings with CPVC pipes.

- Pressure and temperature ratings: Fittings must match or exceed pipe specifications.

- Proper joining methods: Solvent welding, threading, or compression.

Types of Fittings:

- Elbows, Tees, Couplings

- Union Joints

- Valves, Adapters

Oriplast provides a complete range of high-quality, precision-molded fittings, ensuring secure, leak-proof connections for solar installations.

Installation Best Practices

Professional or DIY, follow these tips for lasting performance:

- Correct Sizing: Match pipe diameter to system flow rate and pressure.

- Secure Joints: Use Oriplast-approved solvent cement for CPVC.

- Insulate Properly: Especially for outdoor or roof-exposed lines.

- UV Protection: Wrap exposed pipes or use UV-rated materials.

- Pressure Testing: Always test for leaks post-installation.

Why Choose Oriplast for Solar Piping?

Oriplast is a trusted name in India’s plastic piping industry with over 50 years of experience. Here's why professionals choose Oriplast for solar heating systems:

- High-performance CPVC & PERT pipes

- ISI-certified products conforming to BIS standards

- Leak-proof, easy-install fittings

- Supportive customer service and installer guidance

- Pan-India distribution and service network

Whether you are a homeowner, solar installer, or plumbing contractor, Oriplast offers the products and support to ensure your solar heating system performs reliably and efficiently for years.

Conclusion

Choosing the right pipes and fittings is not just a technical detail—it’s a vital decision that affects the efficiency, safety, and lifespan of your solar water heating system.

CPVC pipes and fittings from Oriplast deliver the performance, reliability, and durability that today’s solar installations demand. With Indian weather conditions and water quality in mind, Oriplast’s engineered solutions ensure your system remains worry-free and cost-effective in the long run.

Ready to Build or Upgrade Your Solar Water Heater?

👉 Explore Oriplast’s CPVC piping solutions 📞 Contact our experts for tailored recommendations 🔧 Insist on Oriplast for safe, efficient, and long-lasting solar water heating systems

Frequently Asked Questions (FAQ)

What type of pipe is best for solar water heating systems?

CPVC (Chlorinated Polyvinyl Chloride) is generally the best choice for solar water heating in residential and commercial applications. It offers high-temperature resistance (up to 93°C), corrosion resistance, and long-term durability, making it ideal for rooftop solar installations.

Can regular PVC pipes be used in solar water heaters?

No. Regular PVC is not suitable for hot water applications because it softens at high temperatures. Always use CPVC or other heat-resistant materials specifically rated for hot water.

How important are pipe fittings in solar water heating systems?

Very important. Fittings ensure leak-proof connections and system safety. They must be made from the same material as the pipes (e.g., CPVC with CPVC) and have equal or higher pressure and temperature ratings.

What’s the difference between CPVC and PPR pipes?

CPVC handles higher temperatures (up to 93°C) compared to PPR (~70°C). While both are plastic piping options, CPVC is preferred for solar water systems due to better heat resistance and chemical stability.

Are metal pipes like copper better than CPVC for solar heating?

Copper has excellent heat tolerance but is more expensive, harder to install, and may corrode depending on water chemistry. CPVC is more cost-effective, easier to install, and offers corrosion resistance, making it ideal for most residential systems.

Do CPVC pipes withstand UV exposure on rooftops?

CPVC can handle moderate UV exposure, but for long-term outdoor use, it’s recommended to apply insulation or protective covering. Some brands, like Oriplast, also offer UV-resistant product variants.

Can I install solar water heating pipes myself?

While CPVC pipes are user-friendly, professional installation is strongly recommended. Proper sizing, joining, insulation, and pressure testing are crucial for safe and efficient operation.

How do I know if a pipe or fitting is suitable for solar water heating?

Check the product’s specifications for:

- Temperature rating (should handle at least 90°C)

- Pressure class (match your system requirements)

- Material compatibility Choose ISI-certified and industry-compliant products like those offered by Oriplast.